Strategies and considerations for designing liquid cooled switch panels

In the current data center and high-performance computing environment, liquid cooling technology is gradually being widely used as an efficient, environmentally friendly, and significantly improving equipment cooling efficiency. Among them, as a key equipment, the panel design of the liquid cooling switch is directly related to the operational efficiency and safety of the entire liquid cooling system. The following will provide a detailed introduction on how to design an efficient liquid cooled switch panel.

Firstly, material selection is the foundation of design. The liquid cooled switch panel needs to be made of materials that are corrosion-resistant, high-temperature resistant, and have good thermal conductivity, such as stainless steel or special plastics, to ensure stable operation in long-term contact with the coolant environment and effective heat conduction. At the same time, the panel should have a certain mechanical strength to ensure structural stability under internal pressure and external environmental changes.

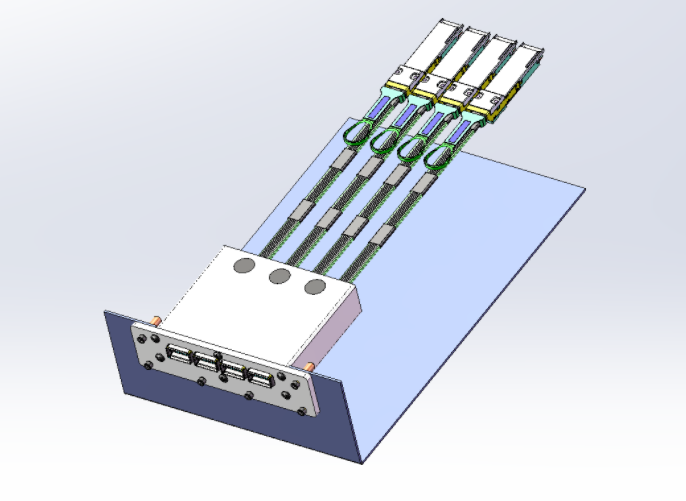

Secondly, channel design is crucial. The interior of the panel needs to be equipped with precise fluid channels to achieve effective contact between the coolant and the core components of the switch, thereby quickly removing the generated heat. The design of the flow channel needs to follow the principles of fluid mechanics, minimize flow resistance, enhance coolant flow efficiency, and prevent the occurrence of "dead water zones" that lead to uneven heat dissipation.

Furthermore, sealing is one of the core requirements for the design of liquid cooled exchange panels. Due to the involvement of liquid circulation, strict sealing measures must be taken at the joints and interfaces of the panel, and reliable sealing components and processes must be selected to ensure that the coolant does not leak, while also preventing dust and other impurities from entering, ensuring internal cleanliness of the equipment and extending its service life.

In addition, considering maintenance convenience and safety factors, the panel should be designed with convenient connection interfaces and quick disassembly and assembly functions for daily inspection, cleaning, troubleshooting, and repair. At the same time, corresponding monitoring systems should be equipped to monitor parameters such as coolant temperature, flow rate, and pressure in real time, ensuring that in case of abnormal situations, timely warnings can be given and corresponding measures can be taken.

Finally, human-computer interaction design is also essential. The functions and status indicators of each major component should be clearly marked on the panel to facilitate operators to intuitively understand the operation status of the equipment. An intelligent management system can be set up to achieve remote control and automated management.

In summary, designing a liquid cooled switch panel is a complex task that integrates multiple fields such as material science, fluid mechanics, sealing technology, and ergonomics. It is necessary to fully consider the actual operating conditions, heat dissipation requirements, safety protection, and maintenance convenience of the equipment, in order to create efficient, reliable, and user-friendly liquid cooled switch products.

White Box specializes in designing network connectivity solutions for various complex applications. If needed, please contact sales@pcie.com.