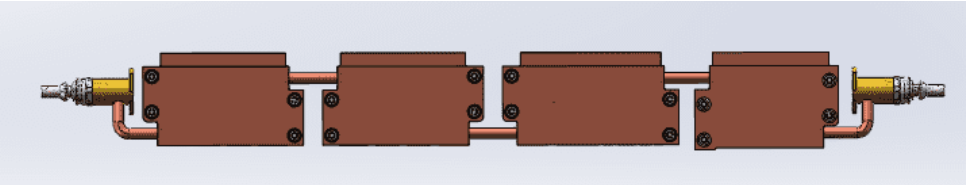

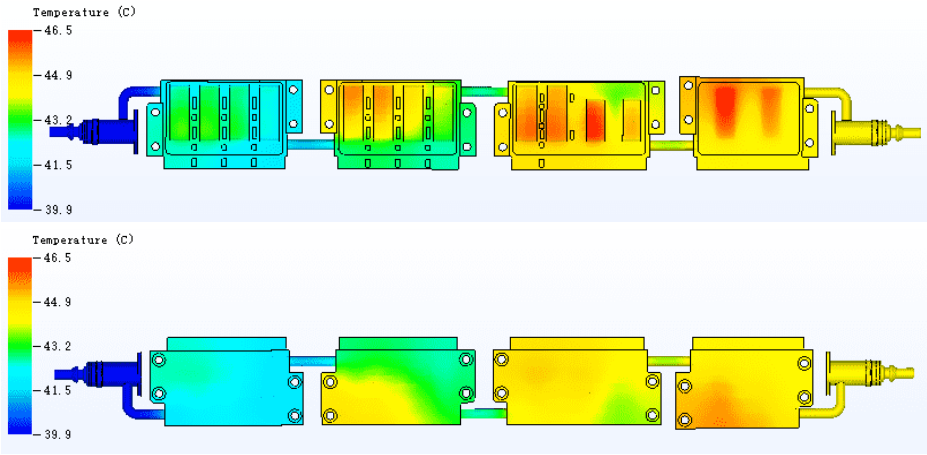

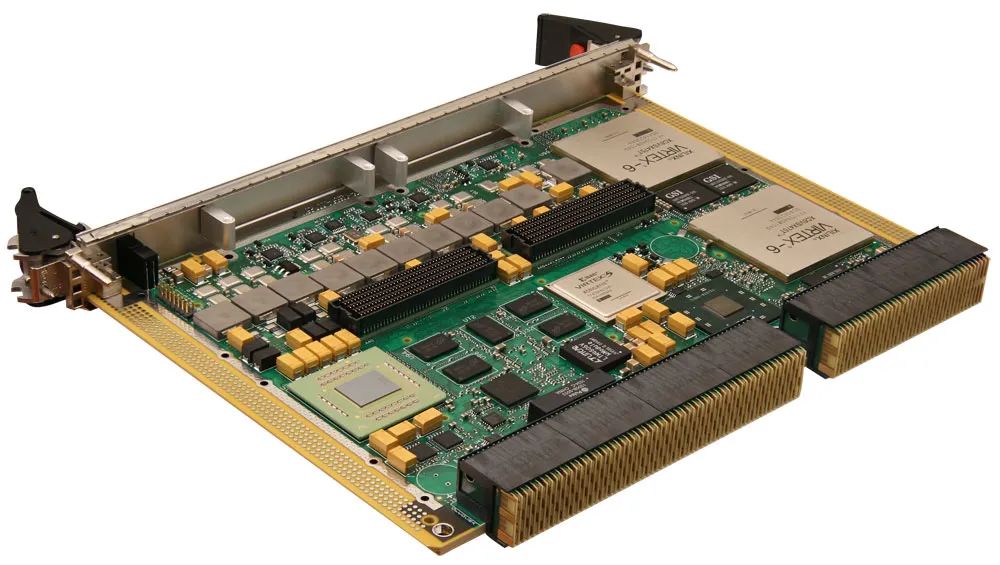

Liquid cooling has been a recognized approach to conditioning electronics for over half a century. Immersion Cooling, which lies at the core of Immersed Computing, involves fully submerging electronic components in a dielectric liquid. This allows all the heat generated by the IT equipment to be trapped within the liquid. Electric liquids with suitable properties can absorb approximately 1500 times more heat energy than air at the same volumes and temperatures.

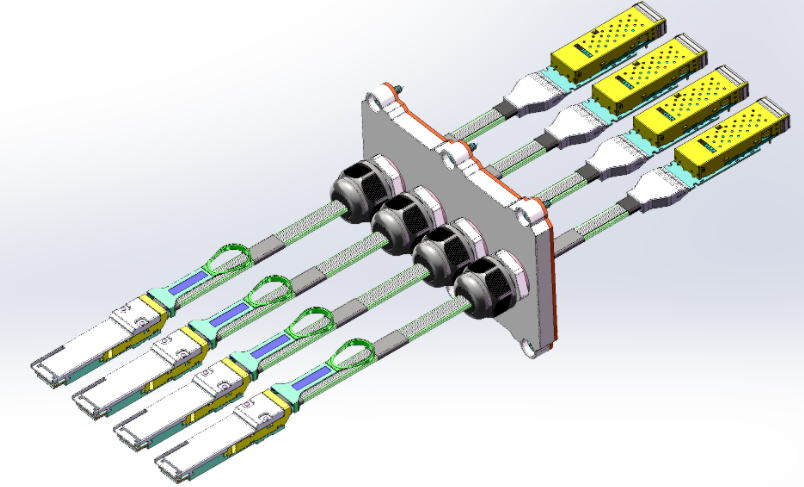

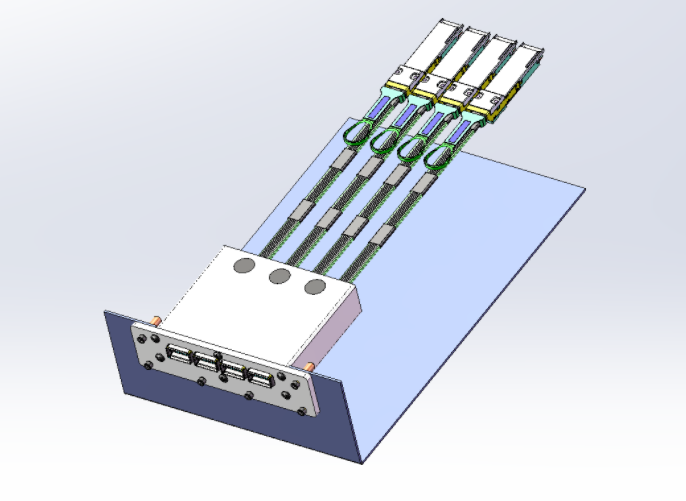

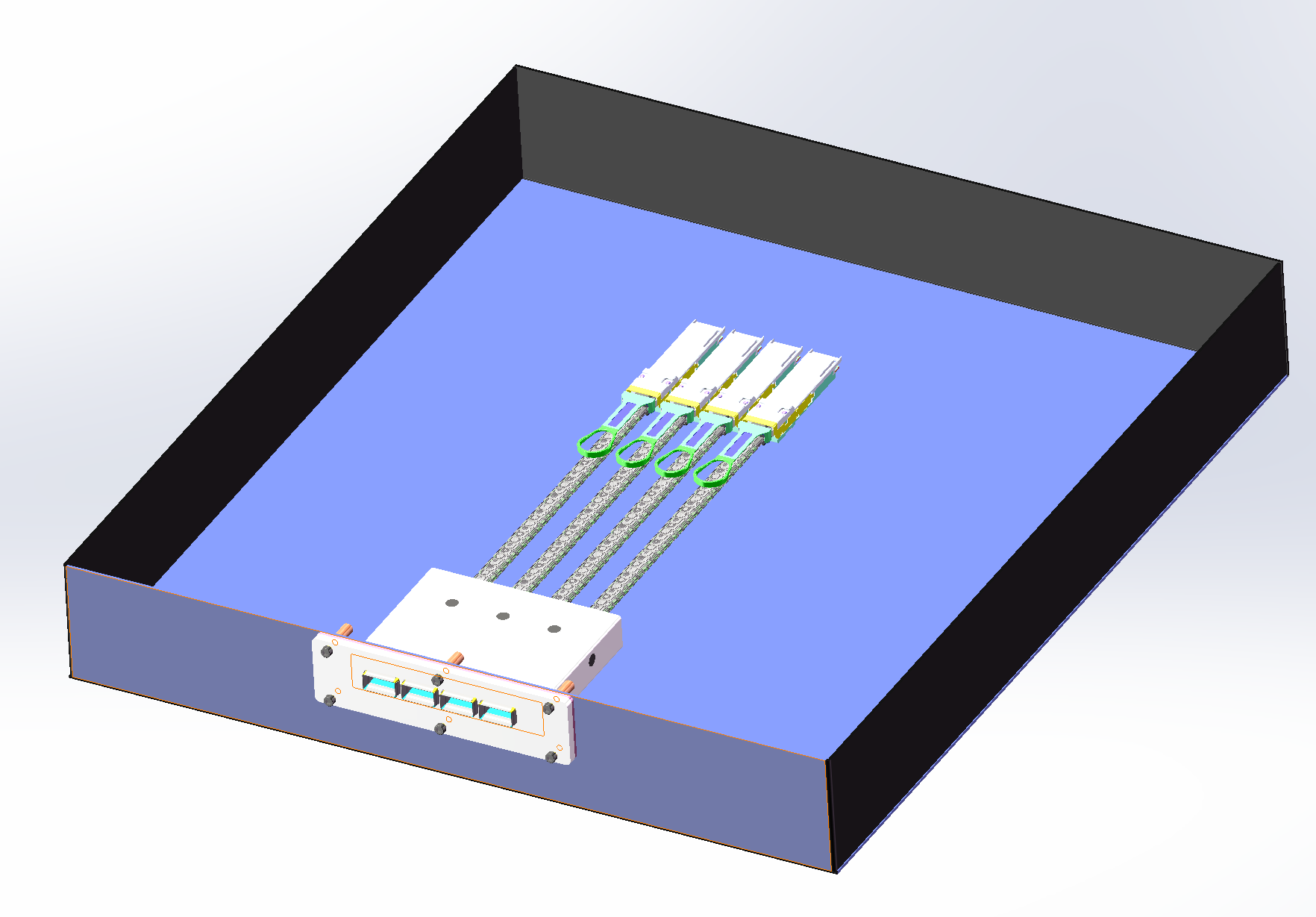

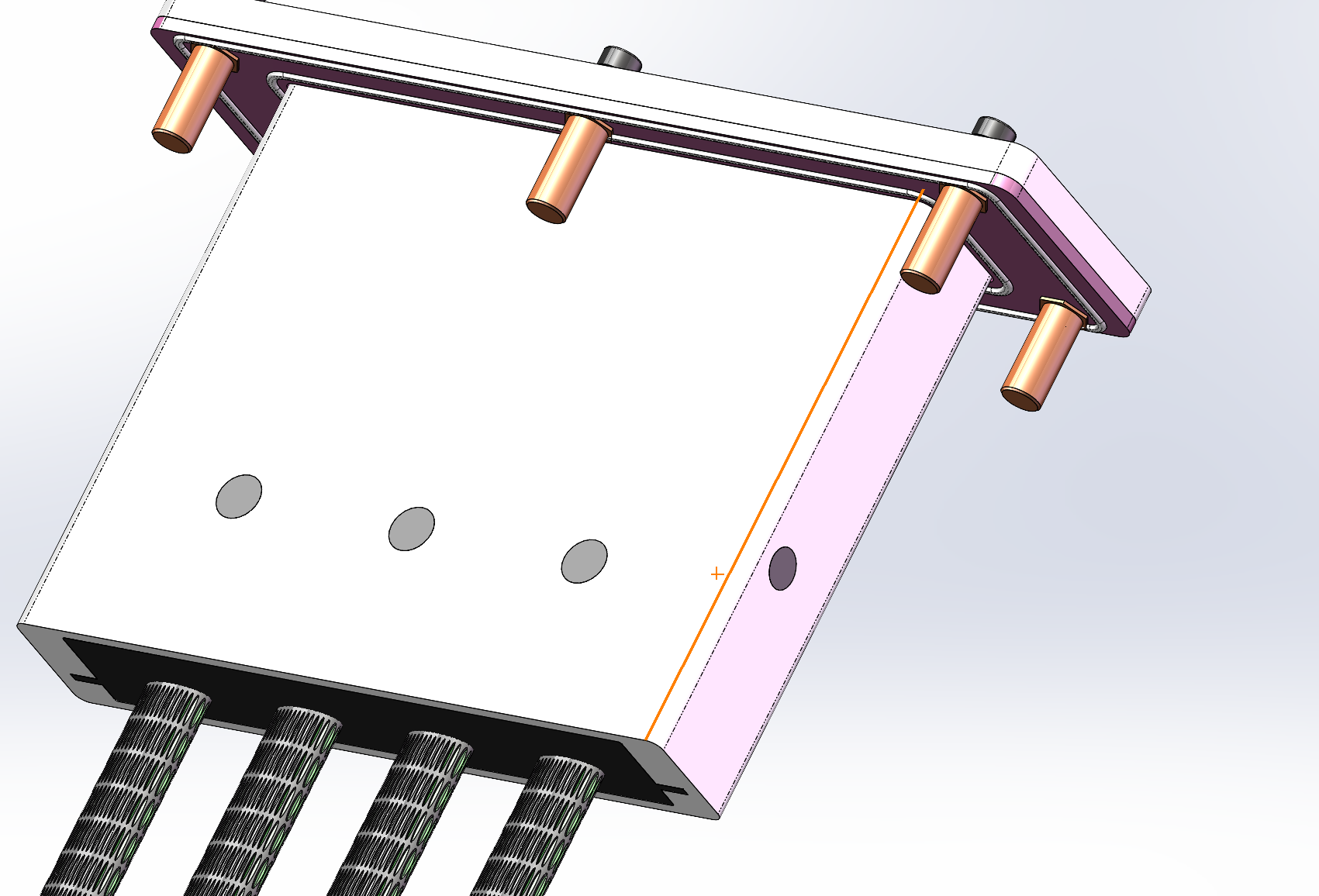

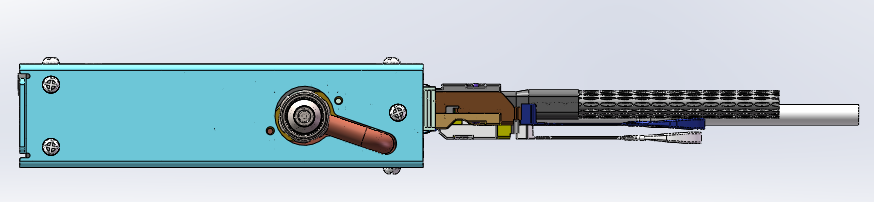

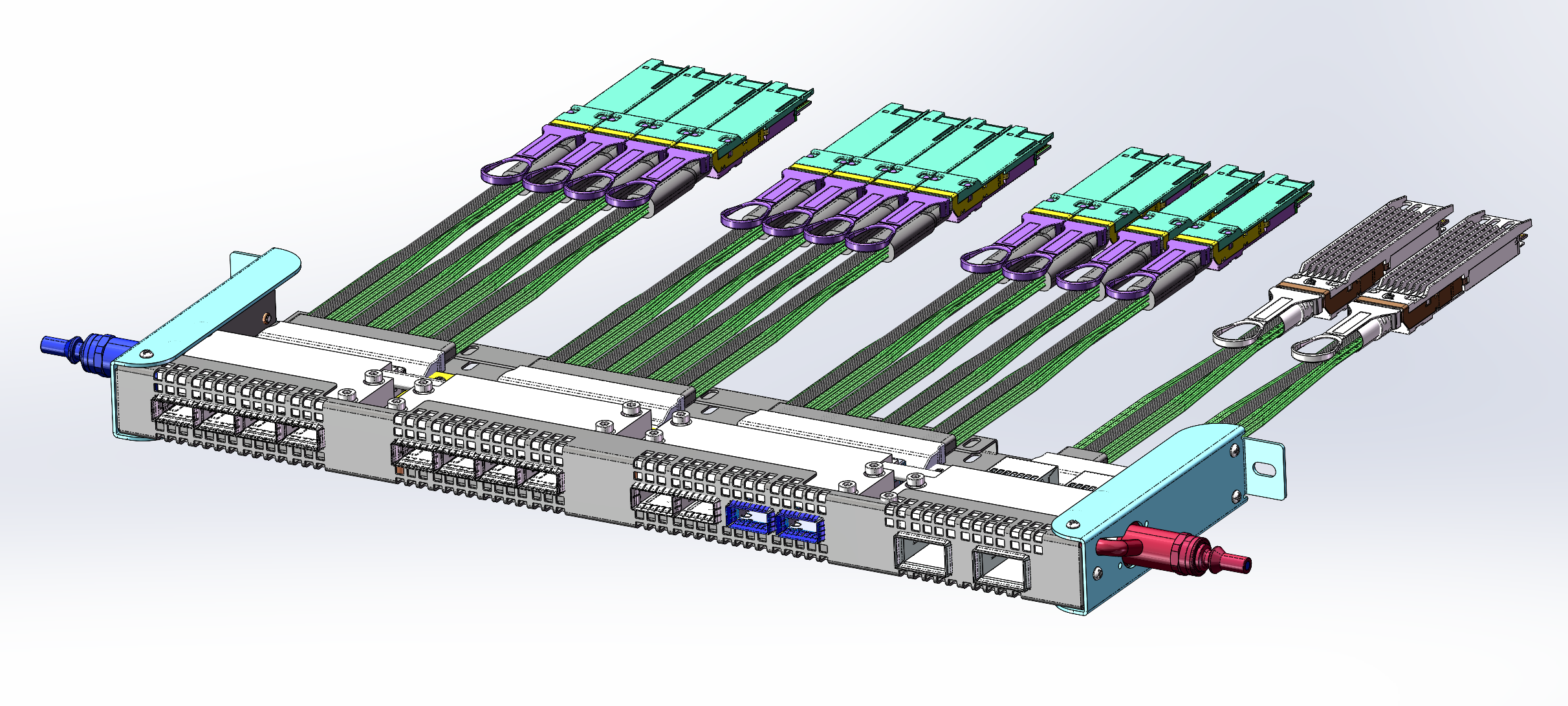

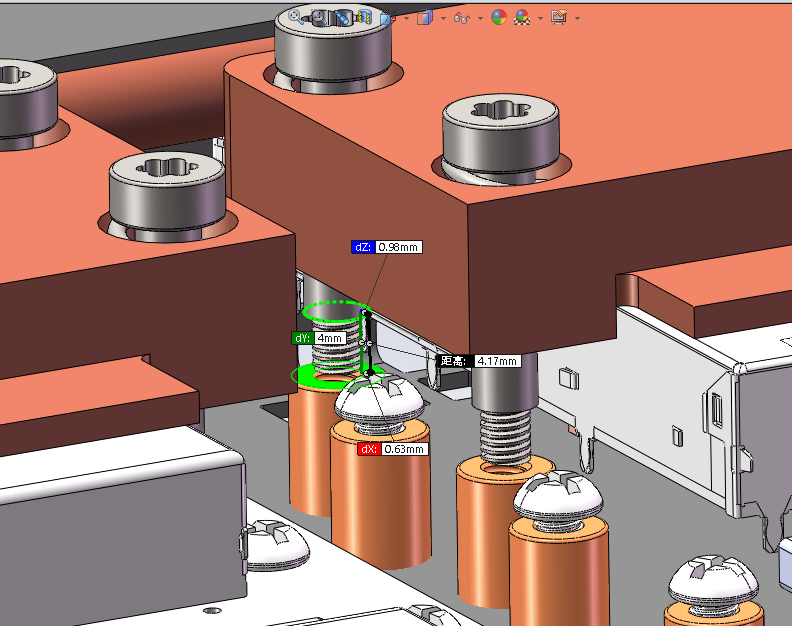

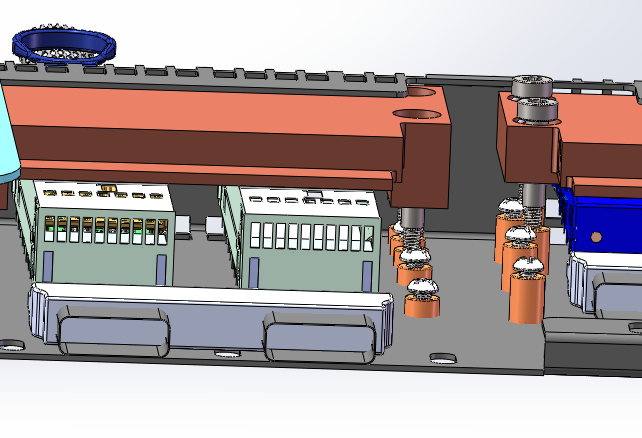

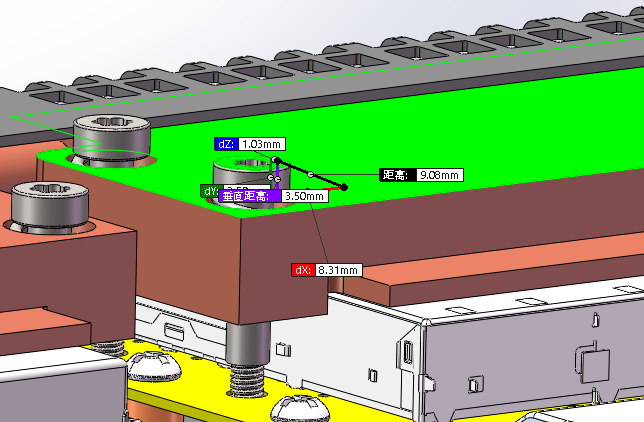

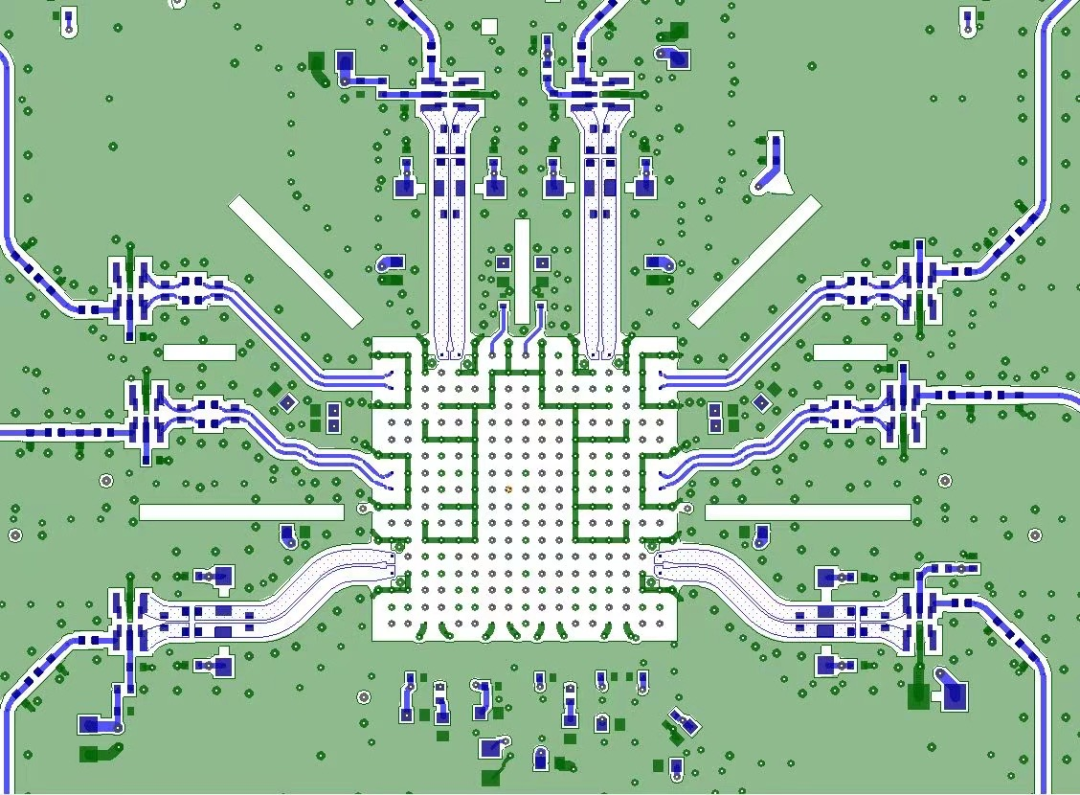

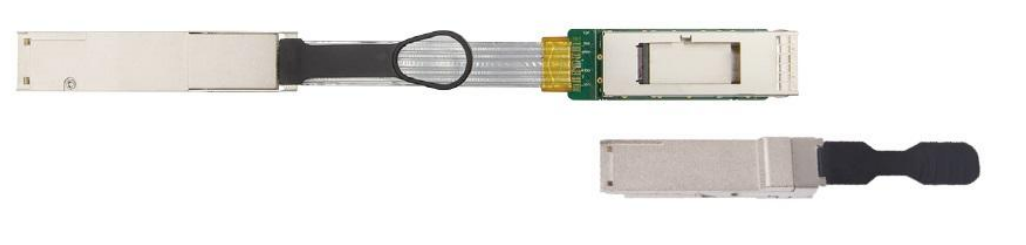

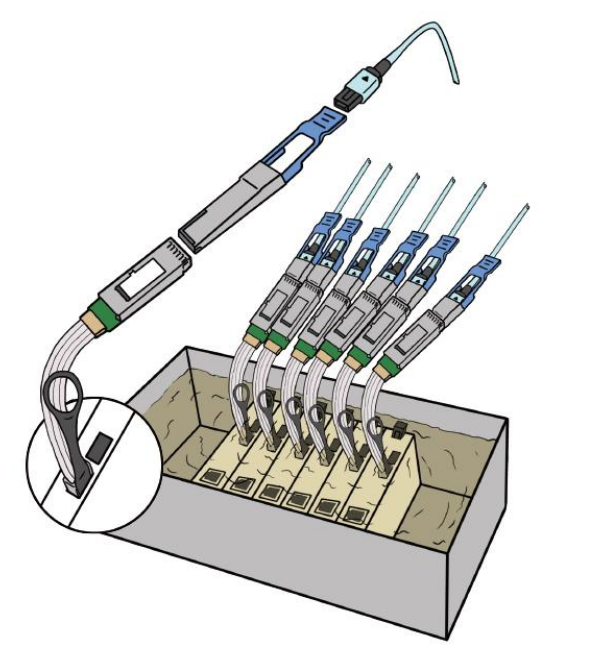

In terms of device temperature control, the adoption of immersed computing design is becoming a trend. However, the performance of fiber lenses deteriorates in liquids, making it impossible for the I/O link to support the deployment of transceivers and active optical cables. To address this issue, a white-box designed extender cable is developed to be used in immersion solutions. This cable extends optical interfaces into the air, aiming to achieve the interconnection of transceivers and active optical cables.

Features

- QSFP28 MSA and SFF-8665 Compliant

- Low EMI radiation

- Insertion Loss -4.5dB at 100G Application

- Oil-resistance, dust-proof and anti-corrosion

- 100 ohm differential impedance system

- Low Near-End Crosstalk (NEXT)

- Customization EEPROM mapping for cable signature

- RoHS compliant

Applications

- Extend the high speed interconnection for liquid immersion solution

- Extend the link of AOCs

- Extend the link of transceivers

Ordering Information

| P/N | Description | Lengths |

|---|---|---|

| WB-S/S | 10 Gb/s SFP+ to SFP+ Cage, with 3M Flat Cable in Nylon Jacket | 10cm/20cm/30cm/55cm/75cm |

| WB-ZSP/ZSP | 25 Gb/s SFP28 to SFP28 cage, with 3M flat cable in nylon jacket | 10cm/20cm/30cm/50cm |

| WB-Q/Q | 40 Gb/s QSFP+ to QSFP+ Cage with 3M Flat Cable in Nylon Jacket | 10cm/30cm/65cm |

| WB-ZQP/ZQP | 100 Gb/s QSFP28 to QSFP28 cage, with 3M flat cable in Nylon Jacket | 10cm/20cm/30cm/50cm |

| WB-QDD/QDD | 200 Gb/s - 400 Gb/s QSFP-DD to QSFP-DD cage, with 3M flat cable in nylon jacket | 10cm/20cm/30cm |

| WB-Q56/4ZQP | 400 Gb/s QSFP56 to 4x QSFP28 cage, with 3M flat cable in nylon jacket | 10cm/20cm/30cm |

| For more available options, please contact for detailed information. | ||

For pricing and more detailed information, please contact sales@pcie.com.