How to design a liquid cooled switch panel that balances safety, efficiency, and easy maintenance?

Designing a liquid cooled switch panel that balances safety, efficiency, and ease of maintenance is a process involving multiple technical and engineering practices. Here are some key design points:

1. Safety design:

The primary consideration is liquid sealing and leak proof design. The panel should adopt advanced sealing technology and dual protection mechanisms, such as using high-precision sealing rings, redundant sealing layers, and leak detection systems. In case of coolant leakage, an alarm should be issued in a timely manner and the cooling cycle should be cut off to prevent equipment damage and potential safety risks. In addition, the panel material should comply with electrical insulation requirements to avoid short circuits caused by liquid contact.

2. Efficient heat exchange design

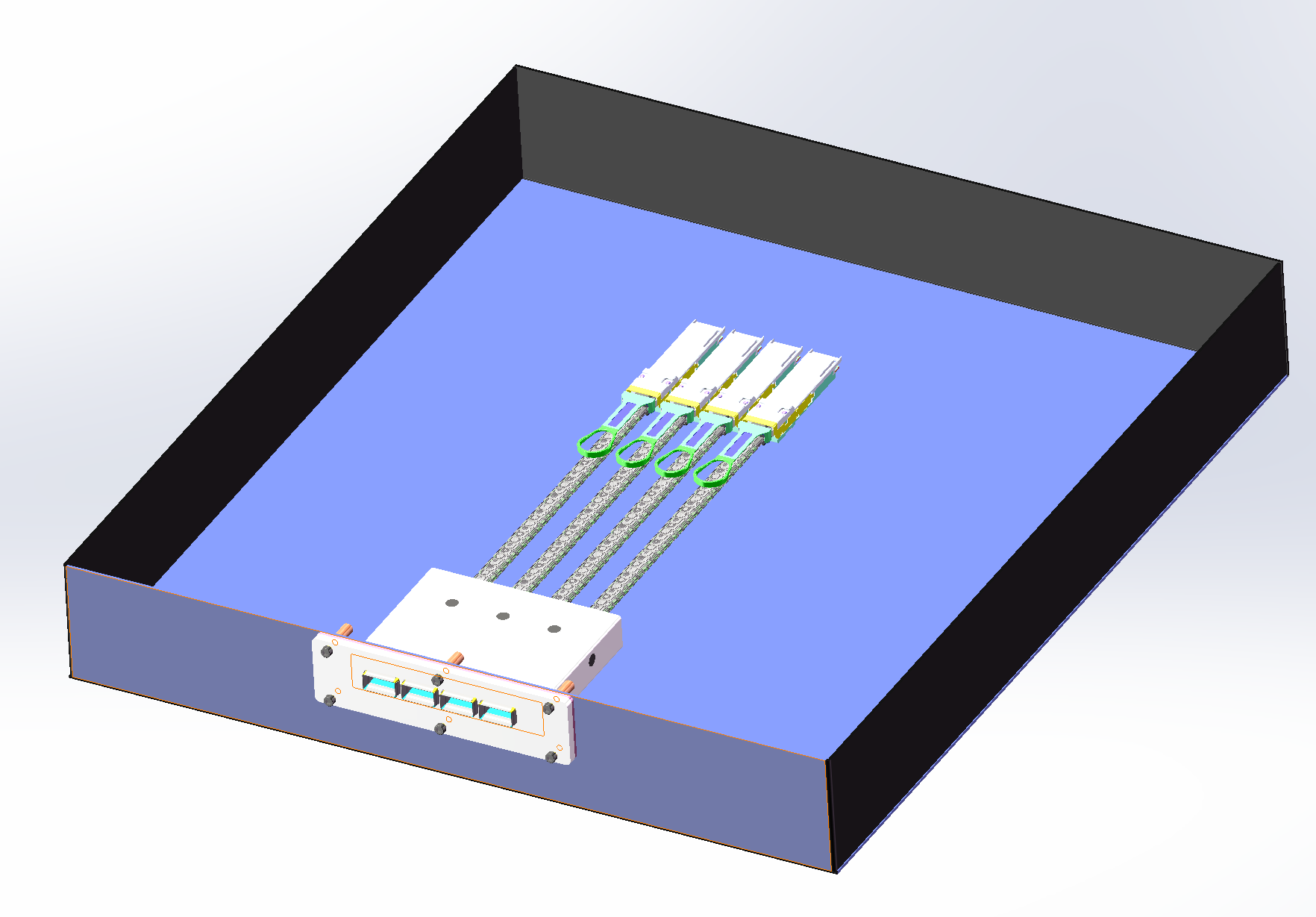

The panel integrates efficient heat dissipation components such as microchannels or heat pipes, allowing the coolant to closely contact the internal heating components of the switch and quickly and effectively transfer heat. At the same time, optimizing the fluid flow path, reducing resistance, and increasing coolant flow rate to enhance overall heat dissipation efficiency.

3. Modular and easy to maintain

The panel should adopt a modular design, and each liquid cooling unit can be independently disassembled and assembled for easy daily maintenance and troubleshooting. Quick plug interfaces can be set up to simplify the pipeline connection process and reduce the time and cost of assembly and maintenance. Meanwhile, design a monitoring interface that is easy to observe and read, providing real-time feedback on the working status of the liquid cooling system, including important parameters such as temperature, pressure, and flow rate.

4. Humanized operation design

The panel layout should be concise and clear, with reasonable positions for various interfaces, valves, displays, etc., to facilitate operation and maintenance personnel. If necessary, an intelligent control system can be configured to achieve remote monitoring and automated management, further improving operational efficiency.

In summary, designing a liquid cooled switch panel is not just a technical issue, but also requires comprehensive consideration of factors such as safety, efficiency, and maintenance convenience. Through scientific and reasonable structural design and intelligent control methods, it is ensured that the liquid cooled switch performs optimally in practical applications.

White Box specializes in designing network connectivity solutions for various complex applications. If needed, please contact sales@pcie.com.